Vacuum inside the closed mold is achieved using a 4,000-litre tank made by Fondarex in Switzerland.

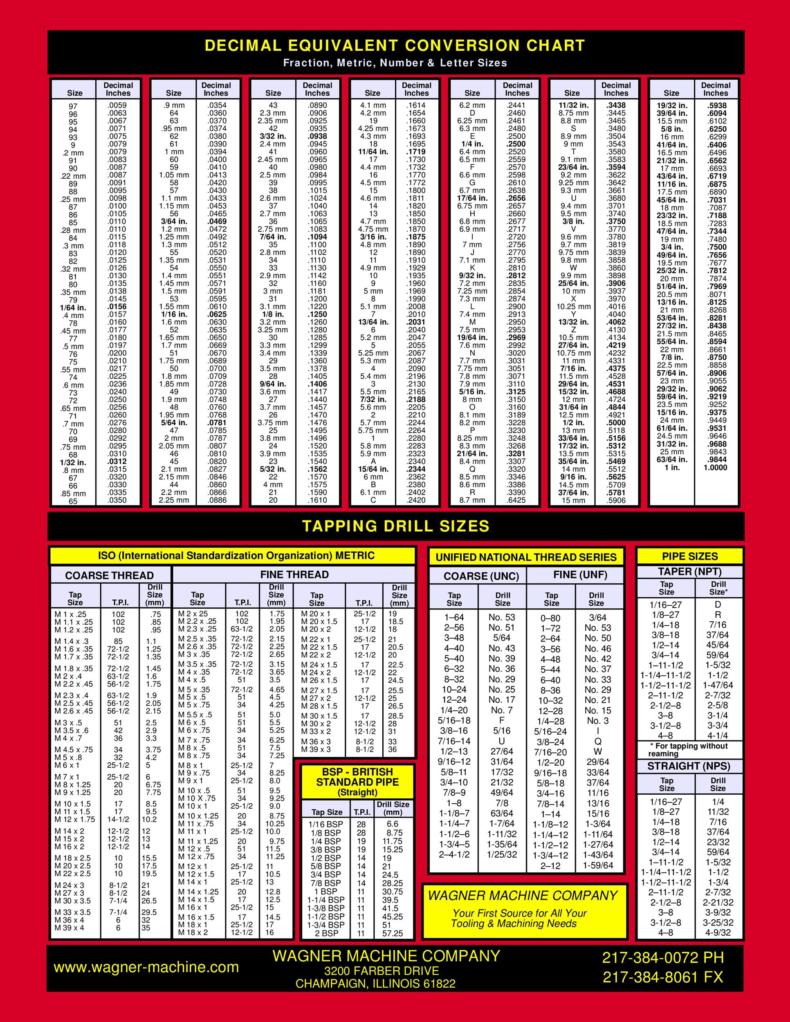

FORMING TAP DRILL CHART PLUS

Metal alloy Īccording to analysis by Sandy Munro of a Model 3 casting in 2021, the casting aluminium alloy used in the large Tesla chassis parts is primarily an aluminium 89.5%‒ silicon 8.5% mix, plus several other trace elements, falling within the categorisation of Aluminum Association alloy "AA 386":Īnalysed alloy composition of Tesla Model Y megacasting Element The front casting suggests an identical die layout, with maybe a 5th wedging die underneath (process) for the front-facing (car) crash rail mount. 2 smaller side wedging dies, moving in for injection and out for removal.2 big classic main facing dies, oriented vertically with injection from the bottom of the immobile one.Tesla's Model Y rear casting dies has four known visible parts: The remaining useful part of the casting is X-rayed to check the internal structure, trimmed by laser, drilled for fittings, and then computer-measured for accuracy. A mechanical trim press cuts the approximate edges, with excess aluminium being recycled back into the melting oven. Ī robot reaches in and removes the casting, placing it in a quenching tank to reduce the temperature from 400 to 50 ☌ (750 to 120 ☏). The mold is opened, and the raw casting removed at 400 ☌ (750 ☏). A precise amount of molten metal is pumped from the holding oven into the casting chamber of the Giga Press at 750 ☌ (1,400 ☏), and forced into the mold using a high-speed plunger with an additional 8 millilitres (0.28 imp fl oz 0.27 US fl oz) of lubricant. The mold is closed, and a low vacuum of 50 millibars (50 hPa) created by pumping out the air from inside. Īt the beginning of each casting cycle robots spray 35 millilitres (1.2 imp fl oz 1.2 US fl oz) of soybean oil in a thin layer inside each half of the mold to allow separation. Argon gas and a rotary- degasser are used to remove impurities, with a silicon carbide filter removing most other particles larger than 25 micrometres (1 thou). To prevent the formation of oxides, a tank blanket of nitrogen gas covers the molten aluminium, which is circulated to maintain an even temperature.

Slag in the form of aluminium oxide is mechanically removed from the surface, and the rest of the liquid metal is pumped through heated pipes to an enclosed warming oven operating at 750–850 ☌ (1,400–1,600 ☏), heated using 400 kilowatts (0.4 MW) of electrical power. įor the Tesla's Giga Press-based casting operation, ingots and off-cuts of aluminium are melted in a natural gas-powered melting oven operating at 850 ☌ (1,600 ☏), until liquid. Each fresh casting is trimmed to approximate size, measured, checked for imperfections, and sent for CNC machining to finished size. The open mold is cooled to 185 ☌ (365 ☏) and cleaned by robots, and fresh molten aluminium is prepared for the next cycle to begin 1‒2 minutes after the first cycle.

Giga Press in closed position during casting + after removal of previous casting and in open position for robot removal of casting + cleaning.ĭie casting works by forcing molten metal alloy inside a reusable mold, then opening the mold to remove the finished piece after it has solidified. The cycle time is ~80‒90 seconds, allowing an initial output rate of 40‒45 completed castings per hour, or ~1,000 castings per day. įor the Model Y, shots of molten aluminium weighing 80 kilograms (180 lb) are injected into the cold-chamber casting mold with a velocity of 10 metres per second (22 mph 36 km/h). in late-2020 for the production of chassis parts for the Tesla Model Y.

īase specification Giga Press machines have been included in Idra's catalogue since 2018, with usage of a custom OL 6100 CS Giga Press begun by Tesla, Inc. Idra presses are notable for being the largest high-pressure die casting machines in production as of 2020, with a clamping force of 55,000 to 61,000 kilonewtons (5,600 to 6,200 tf).

FORMING TAP DRILL CHART SERIES

The Giga Press program is a series of aluminium die casting machines manufactured for Tesla, initially by Idra Group in Italy.

0 kommentar(er)

0 kommentar(er)